GPT are experts in the installation and maintenance of FilterSepta systems. These above-ground interceptors work in conjunction with automatic bund dewatering devices.

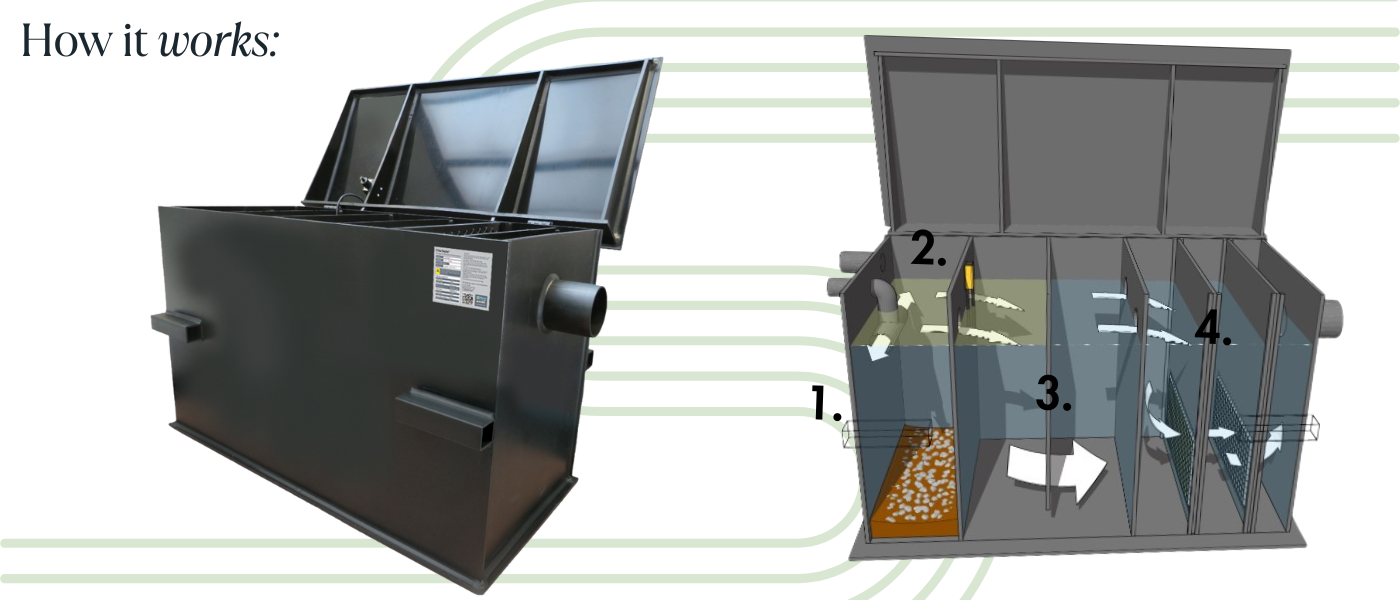

Above Ground Oil Interceptor

For sensitive site conditions only, (where there is no underground interceptor tank), we recommend FilterSepta. FilterSepta is a cost-effective above ground system that guarantees a Class 1 discharge of water from the bund to surface water adhering to BS EN 858-1:2002.

These interceptors use phase separation and coalescing devices to remove any emulsified oil or debris, however small, still present in the pumped water from the automatic bund dewatering device.These systems are ideal for both new and retrofit installations, and allow for safe discharge through surface water drainage.

Key Benefits

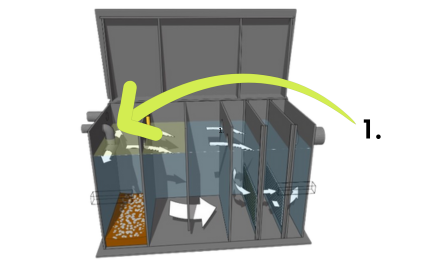

1

Water enters through T-section to prevent the bottom of the chamber being disturbed by the water flow - allowing any silt & heavy solids to settle at the bottom.

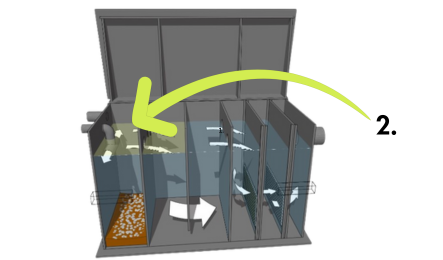

2

Free oil will separate and form a layer at the top which then flows into the next chamber.

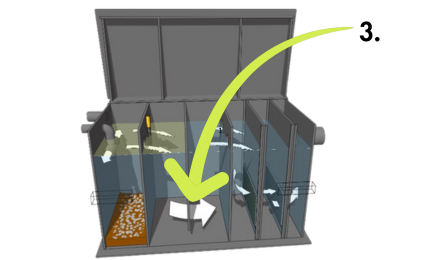

3

The outlet from the 2nd to 3rd chamber is at the bottom of the system, so only water that is free of oil is allowed to pass through.

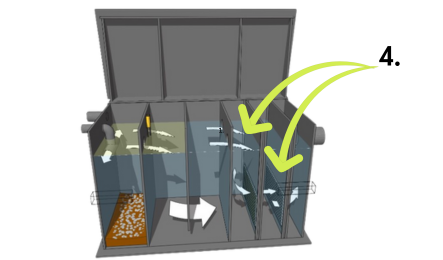

4

Finally, two coalescing filters serve to remove any remaining suspended solids and emulsified oils, before discharge of the filtered water.

If, over time, there is a significant build-up of oil in the second chamber, there is an oil sensor that will shut off the automatic bund dewatering device, and alert the site of an issue.